With power densities around 7000 W/kg, GMG claims its graphene aluminum-ion battery technology could charge a phone battery in 1-5 minutes

Australian company Graphene Manufacturing Group (GMG) has announced exciting performance test results for a new type of aluminum-ion battery that can charge 10X faster than today’s lithium-ion units, while lasting much longer and needing no cooling.

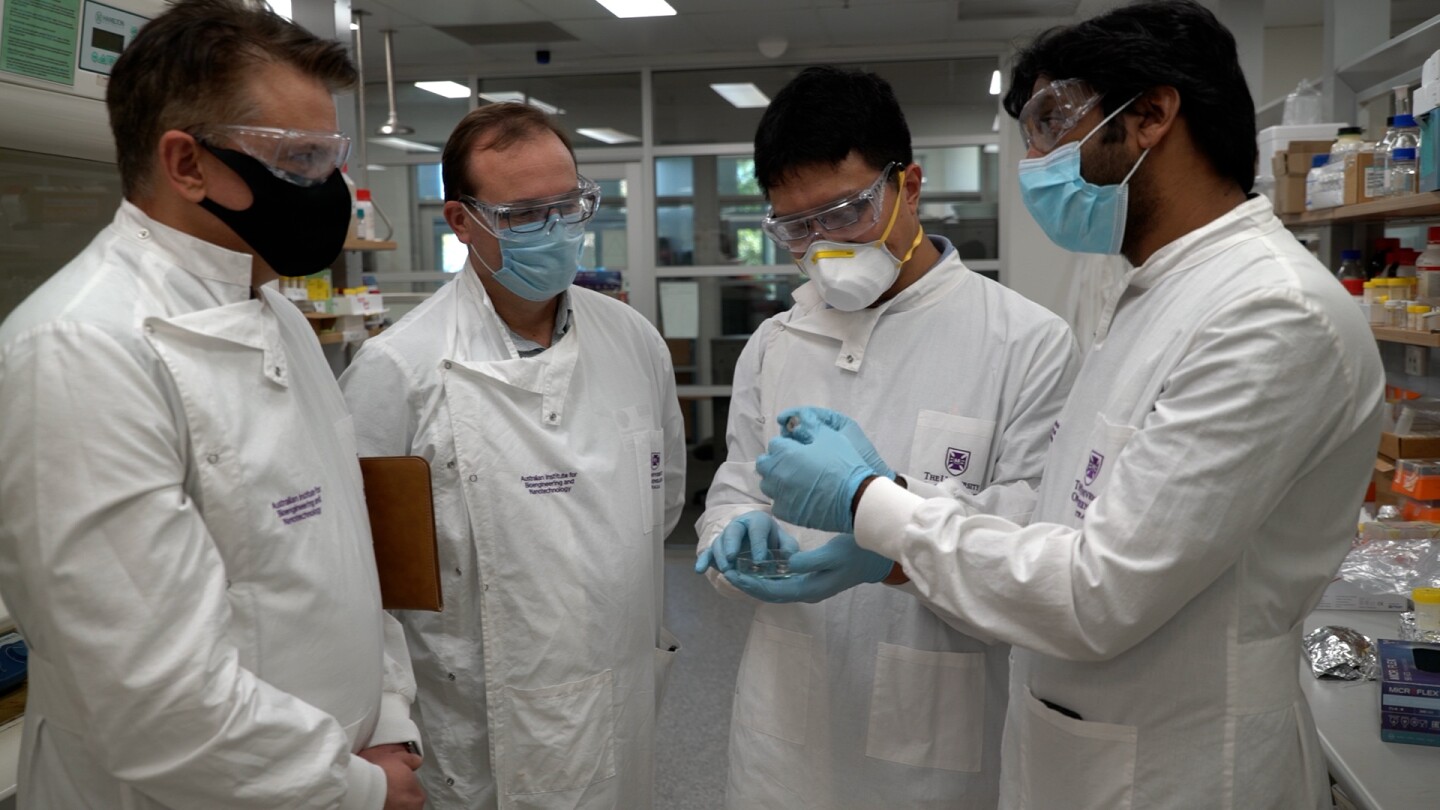

In experiments performed by the Australian Institute for Bioengineering and Nanotechnology at the University of Queensland, coin cell prototypes of the new battery delivered the following key performance figures.

Firstly, a power density around 7,000 W/kg. Power density puts a number on how quickly a cell can charge and discharge. With current lithium-ion batteries sitting between 250-700 W/kg, this is a huge leap, and it puts the aluminum-ion battery nearly on the level of ultracapacitors, which can deliver around 12,000-14,000 W/kg.

Secondly, an energy density of 150-160 Wh/kg – so it carries only around 60 percent of the energy per weight of today’s best commercial lithium-ion cells.

Energy density has long been the key spec sheet number for electric car batteries; the greater the energy density, the more range you can get out of your battery pack. So on energy density alone, this new GMG battery wouldn’t get a second glance from an EV manufacturer.

But its monster charge rate could change that, along with a couple of other key advantages. These things can charge so fast, says GMG, that a mobile phone running on this aluminum-ion tech could get a full charge in 1-5 minutes. Take that concept across to the electric car world, and you’re looking at an EV that travels 60 percent as far as an equivalent Tesla on a charge, but that charges so damn fast that range might become far less of an issue.

What’s more, they vastly outlast lithium batteries in life cycle testing, undergoing 2,000 full charge and discharge cycles with no apparent deterioration in performance at all, they are extremely safe, with low fire potential, and they’re more recyclable than lithium batteries too, at the end of their useful life. And yes, they need no lithium. With some 90 percent of the world’s lithium production and purchasing running through China, the world’s supply chains are definitely vulnerable in trade disputes.

Another ace up the GMG battery’s sleeve is outstanding thermal performance. Even when they’re charging and discharging at enormous rates, they don’t seem to overheat. “So far there are no temperature problems,” said GMG managing director Craig Nicol in an interview with Forbes. “Twenty percent of a lithium-ion battery pack (in a vehicle) is to do with cooling them. There is a very high chance that we won’t need that cooling or heating at all. It does not overheat and it nicely operates below zero so far in testing. They don’t need circuits for cooling or heating, which currently accounts for about 80 kg in a 100 kWh pack.”

That fact changes the range equation; taking the 100 kWh battery described above, a GMG battery of the same weight would only carry 60 kWh. But if the extra 80 kg of cooling gear isn’t needed, the GMG-powered car can run an extra 80 kg of cells, which would give you a total of 72.8 kWh, according to the back of our envelope – along with massively faster charge rates that could pretty much put an end to range anxiety.

That seems like a pretty compelling tradeoff, particularly in a battery that might well outlast a few vehicles before it gets retired.

But – and there’s always a but with these things – there are other considerations.

One is charging infrastructure. Mobile phones can charge up quickly without frying the power grid, but electric cars simply can’t right now. Tesla’s Superchargers already pump electrons at rates up to 250 kW – representing a 60 kWh energy transfer in about 15 minutes. If you want to charge just 10 times faster than that, you need to be able to instantly supply 2.5 megawatts at the charge cable.

For reference, a typical coal-fired power station has a total output around 600 megawatts – so if 240 of these ultra fast charging cars happened to plug in at the same time, they’d put an instant load on the power grid equivalent to a whole power station. That’s charging 10 times faster than today’s batteries; GMG says it might be able to charge 60 times faster than some cells.

So super-fast charging electric vehicles are definitely going to be difficult to scale, particularly as the world moves toward renewable energy sources rather than things like coal and gas that can rapidly fire up to meet spikes in demand. And even if the charge stations had their own fast-discharge energy storage on site, trickle charging from the grid at slower rates, you’d also need a heck of a cable from the box to the car to move that many electrons that quickly.

Another is the key ingredient in GMG’s battery – the porous graphene in and around which the aluminum molecules are diffused in GMG’s manufacturing process. GMG says it can produce high quality graphene at low cost and in scalable quantities, but doesn’t put any figures on what these batteries could cost if manufactured at scale. With graphene prices sitting around US$100 per gram, even a “low cost” version could end up being pretty damn pricey.

And the final one is the timeline. As you’re surely painfully aware, there tends to be a bit of a gap between the test bench and the final product; even more where automotive companies are concerned. GMG says it’ll be making coin cell prototypes for very small scale customer testing by the end of this year, with pouch cells in the works, but there’s no indication of when these things might hit the market at scale.

The company didn’t develop the battery tech itself; it was originally developed at the University of Queensland and the test results have been published in the journal Advanced Functional Materials.

Still, there are no guarantees in the battery game, and it’s anyone’s guess whether GMG will get this thing manufactured in scale at a competitive price. But the technology itself definitely seems promising.

Sources: GMG, University of Queensland via Forbes